13/11/2014

My last proper weekend in the shop for 2014 has now come and gone. It is therefore now time to start reviewing what I have managed to accomplish during this year and to take a quick look around the shop.

It all started with the rehabilitation of the two planes I happened to buy at an antiques sale in RSA over the December holidays. The Bedrock no. 606 has become one of my go-to tools.

http://www.jenesaisquoiwoodworking.com/resurrection-of-two-cast-iron-fore-planes/

I also bought this no.78 Rabbet plane from Stanley at the same auction, but it’s rehab took quite some time as it had several parts missing.

http://www.jenesaisquoiwoodworking.com/stanley-no-78-rehabilitation/

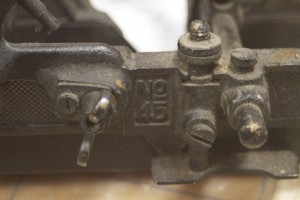

This was the last of my holiday shopping, a no. 45 Plough Plane from Stanley. It was covered with a thick black paint, and had no iron/s. I decided to tidy it up for shop decoration purposes.

http://www.jenesaisquoiwoodworking.com/stanley-no-45-rehabilitation/

I managed to finish turning all those file handles that I started with at the end of 2013.

My major project for 2014 started on the 1st of February and is not finished by quite some way. I spent at least 80% of my shop time this year working on my 18th century workbench and am pleased to say that it is at least assembled by the end of 2014. You can read all about it in a series of posts entitled “My 18th Century Workbench in progress”

My 17 m³ wood finally completed it’s journey when it took occupation of it’s purpose built shed.

http://www.jenesaisquoiwoodworking.com/the-lumbering-odyssey/

These exquisite chisels from Lie-Nielsen arrived after a wait of several months. I made this very basic storage to keep them out of harm’s way.

http://www.jenesaisquoiwoodworking.com/chisel-storage/

Didi (my son) started his woodworking journey by turning this mallet for himself.

I used an antique brace bit from my father’s collection that had key parts of it’s business end missing to fashion this birdcage awl. It is a real winner.

http://www.jenesaisquoiwoodworking.com/brace-bit-birdcage-awl-also-known-as-bbba/

Didi’s next project was this bird feeder.

I revamped and sharpened this old scissor.

http://www.jenesaisquoiwoodworking.com/scissor-rehab/

This shop high stool saw a bit too much action during the 14 years since I first made it. I re-upholstered it with leather and strengthened the base, while (clearly) not worrying too much about je ne sais quoi.

http://www.jenesaisquoiwoodworking.com/shop-high-stool-facelift/

Didi learnt a few more skills by producing this beautiful Assegaai handle for an old axe we had lying around.

This Miller’s Falls no. 88 joiner gauge was successfully rehabilitated.

http://www.jenesaisquoiwoodworking.com/millers-falls-88-perfection-jointer-gauge-rehab/

The wife and I managed to make a team effort of the re-upholstering of “die rooi bank”.

http://www.jenesaisquoiwoodworking.com/die-rooi-bank/

In order to hand plane the two edges of my benches top parallel, I had to first build this large panel gauge.

http://www.jenesaisquoiwoodworking.com/makeshift-panel-gauge/

In order to create the space for my 18th century bench, I had to rearrange some of the power tools. This planer and radial arm saw were placed on the same steel table and lined up to become each other’s out-feed table.

http://www.jenesaisquoiwoodworking.com/level-playing-field/

A set of winding sticks.

http://www.jenesaisquoiwoodworking.com/shop-made-winding-sticks/

My favourite shop made wooden plane received some cosmetic surgery. I added a thin strip of Tamboti to it’s chipbreaker/lever cap and covered the lever cap screw with Kaapse Swarthout. This is a true workhorse as it makes short work of all scrub plane and very aggressive fore plane tasks.

http://www.jenesaisquoiwoodworking.com/scrub-plane/

My own version of a Melencolia Square.

http://www.jenesaisquoiwoodworking.com/shop-made-melencolia-square-with-the-marxian-improvement/

Custom made leather apron.

http://www.jenesaisquoiwoodworking.com/custom-made-leather-apron/

Restored a Stanley no. 10 Rabbet plane (ca 1900) and a Bedrock no. 607 Jointer.

http://www.jenesaisquoiwoodworking.com/stanley-no-10-rabbet-plane-rehab/

http://www.jenesaisquoiwoodworking.com/stanley-bedrock-no-607-jointer-rehab/

Replaced my ½” Lie-Nielsen mortice chisel handle with a shop made Ysterhout version. So far it is standing up to heavy abuse without breaking a sweat.

http://www.jenesaisquoiwoodworking.com/replacing-lie-nielsen-mortise-chisel-handle/

A custom made pairing handle for my bevel edge chisels.

http://www.jenesaisquoiwoodworking.com/shop-made-pairing-handle-for-my-lie-nielsen-bevel-edge-chisels/

Finally got round to making an Ysterhout straight edge.

http://www.jenesaisquoiwoodworking.com/shop-made-ysterhout-straight-edge/

Restored this Stanley no. 203 bench clamp.

Restored this Stanley no. 9½ block plane.

http://www.jenesaisquoiwoodworking.com/stanley-no-9½-block-plane-rehab/

I started restoring this Stanley no. 8 Jointer (ca 1896), but there is a lot more work to do next year. I will replace both tote and knob.

Tour de Shop at the end of 2014

This is simply a series of photos documenting the state of the shop at the end of 2014. The major change from last year has been the addition of the assembled (though not finished yet) 18th century style workbench. I also managed to collect quite a few new hand tools with the help of Patrick Leach and Jim Bode. As I am writing this my first shipment from Jim has not arrived yet despite leaving the States on the 12th of October. My guess is I will never see those tools or money again. Just one of the joys of living in Africa.

(9/1/2015 – I am very happy to report that the shipment arrived in Namibia on the 6th of Jan 2015 without as much as a scratch. I will write a post on this saga in the near future)