7/9/2015

I managed to do a little bit of work during the evenings last week. One of those tasks were to add two strips of Meranti to the sides of the bench top’s centre beam. These strips comes from a doorframe. A friend of mine Anton Nel, rocked up at my shop a few weeks ago with this doorframe. He is a builder and was working on a house just around the corner from us. The so called carpenter on the site, arrived (as is exceedingly common around these parts) without any tools of his own. He needed to remove about 20 mm from each side of the 80 mm thick frame.

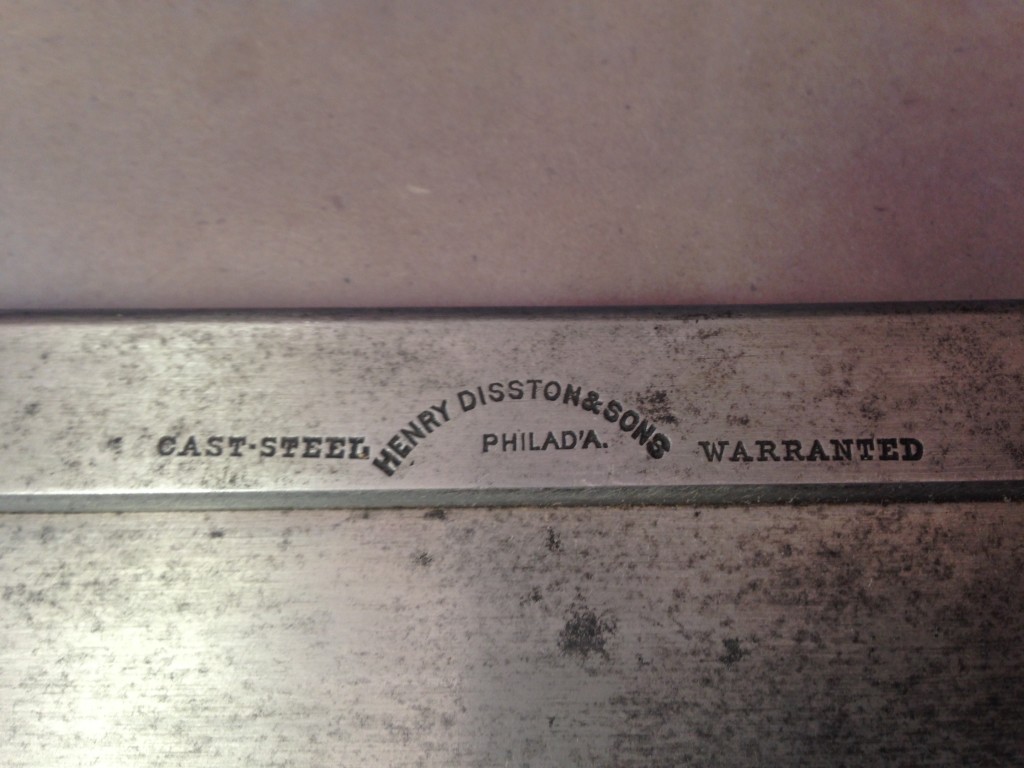

My table saw struggled as it is not made for this dimension of cut, so we decided to cut a 20 mm deep groove from both ends as a guide. We then used my monster 26″ Disston no. 12 rip saw to remove the timber between the grooves. Two cuts of 2 meters each had us both sweating like a gypsy with a mortgage.

It was these offcuts that I planed down to 15 mm (thickness), before gluing and screwing it to the sides of the beam. The idea behind the addition of these strips is to close the gap between the three beams that make up the top to only 3 mm. This will be enough to allow for wood movement, but small enough to prevent most things from accidentally falling through.

In the second and third picture below you can also see the slots I made with my Festool Domino. The three beams making up the top will have several dominos between them to help them to keep each other flush and straight. They will not be glued to allow free movement (horizontal), while only restricting movement in one dimension (vertical).

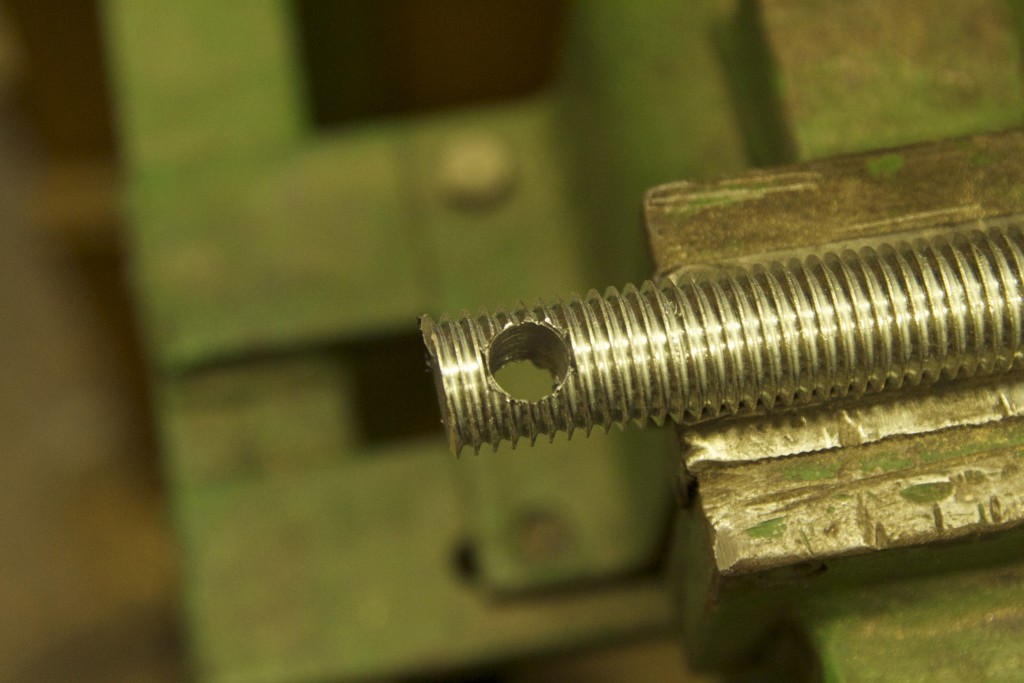

I used my 10 mm bit to cut the Domino slots. Unfortunately I do not have any 10 mm Dominos so I planed some Witpeer down to the desired dimension. Come to think of it, the standard Dominos would have been too short anyway as these will be breaching an 18 mm gap underneath the Meranti strips, extend 28 mm into one beam and 24 mm into the other. The slots are 28 mm deep in both beams, so the extra 4 mm allows for wood movement. In other words, I need to cut my home made Dominos at 68 mm (in length).

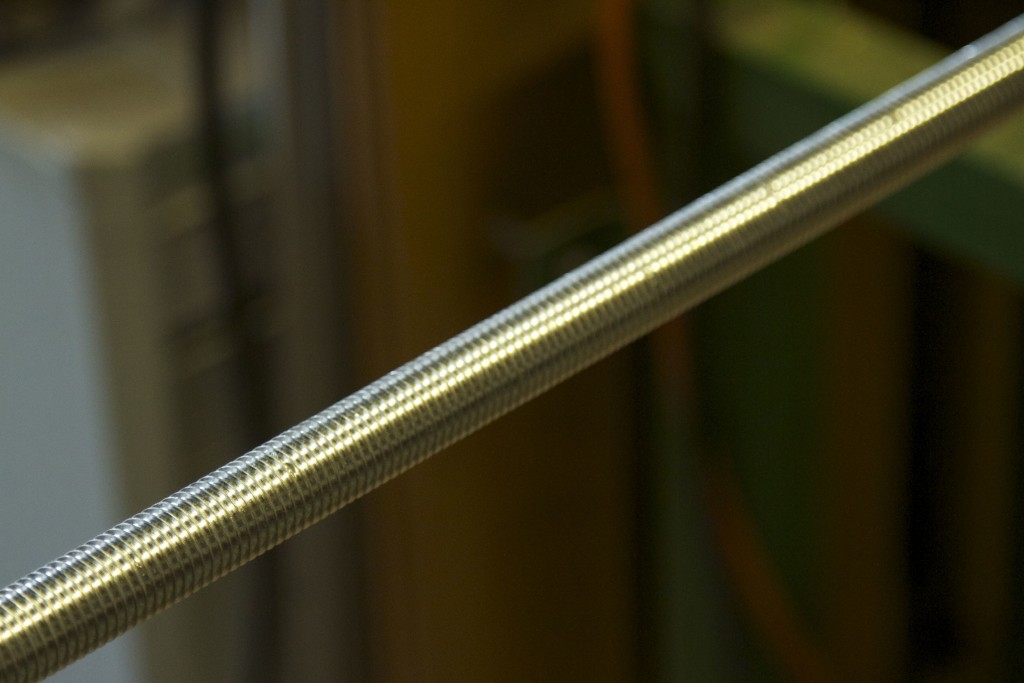

Here you can see how I am progressing with the row of dog/holdfast holes along the front edge of the bench. They are not perfectly in line as the marked difference in hardness between early and late wood cause the auger bit to follow the softer stuff, but I am not overly fussed by this. One could overcome this problem by building a jig, but for this bench it should be fine with the slight meandering of the row.

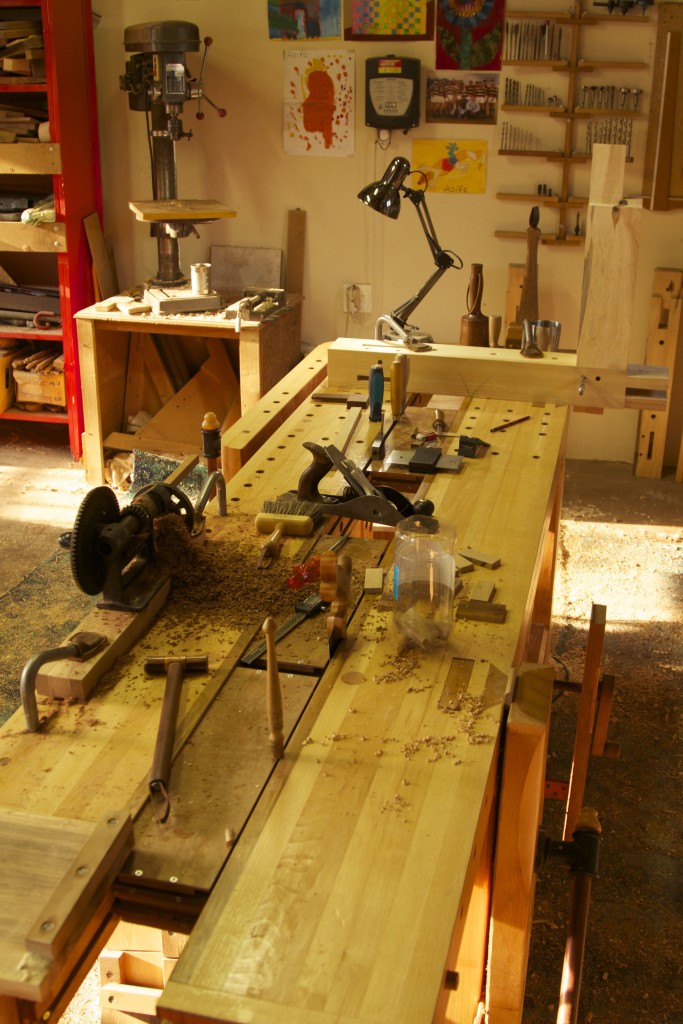

I spent most of my shop time this weekend on fitting the stretchers to their mortices. In the picture below, you can see how my chopping station is on one side of the bench and a station to shave the tenons down on the opposite side. I find it to be a very convenient setup and once again all those dog/holdfast holes come in handy. Monsieur Schwarz might have a heart attack, but he asked to be disobeyed.

For each leg, I first fitted the long stretcher.

In this picture you can see how handy the gap between the split top of my bench can be when fitting through tenons.

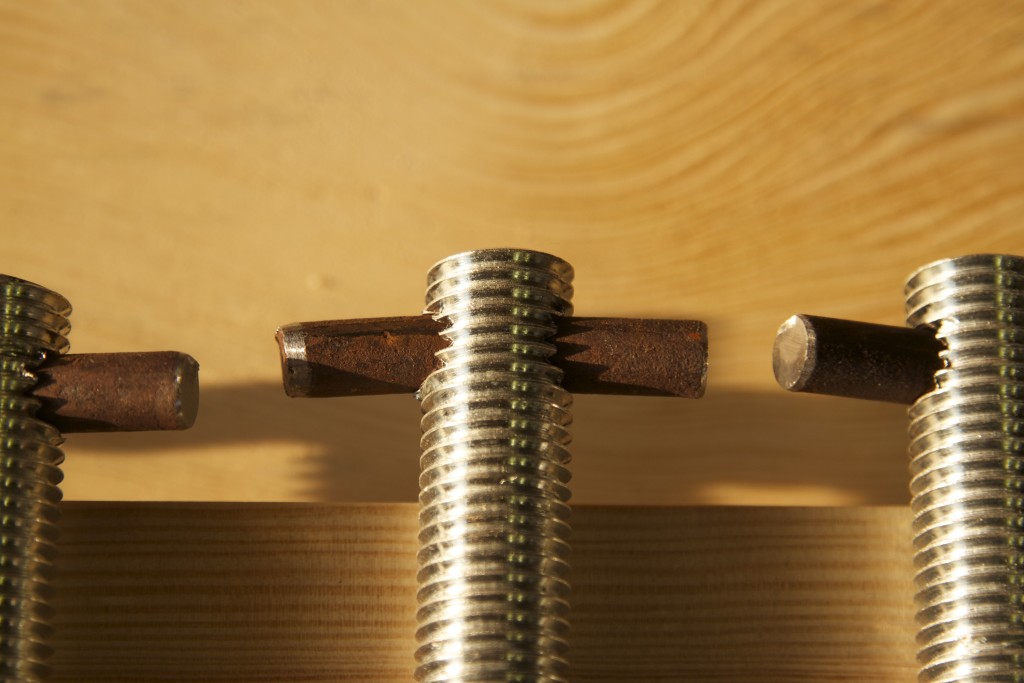

Once the long stretcher’s tenon was in place, I marked out the exact location of the “mortice” that will allow part of the short stretcher’s tenon to run through it.

Next up, the short stretcher being fitted in the absence of the long stretcher.

This picture illustrates nicely how the one tenon pass through the other. As I stated in an earlier post, this is a slight variation to the joinery used in my first bench that was inspired by Japanese joinery.

When fitting massive joints this precise (like a piston, as my friend Jonathan would say), it can be tricky to disassemble them. The picture below illustrate how useful my sliding-deadman-cum-leg-vise proofed to be in this regard. It kept the leg in position at the side of the bench, which allowed me to use both hands to carefully tap the tenon out with a mallet and a small off-cut.

Once that was done I could check whether both stretchers fit simultaneously.

At this stage I started to prepare timber for the shelve between the stretchers. I found two Without (Ilex mitis aka Cape Holly/African Holly) boards in my collect that I thought would go very well with the Scots pine (Pinus sylvestris).

Another reason for this choice concerns the fact that I have not worked with this species before. I am consciously trying to use all the different species in my collection during the shop-setup phase of my journey, in order to get a feel for each. Hopefully by the time I start building furniture it will enable me to make smarter choices.

This is a picture from the internet to show what it looks like once planed and sanded.

The next few pictures should be a reminder to all of you out there who can walk into a lumber yard and pic from hundreds of perfect boards that is ready to use. I have to do a whole heap of work to liberate decent bits of wood from these feral planks. You might be able to see how I marked out the useable areas.

My Disston no. 12 crosscut handsaw took care of all the crosscuts, while the bandsaw made short work of the rip cuts. I decided to keep the shelve’s boards at different widths to waste as little timber as possible and there seems to be a certain je ne sais quoi about the utilitarian appearance it creates.

As I said, at least there is minimal wastage this way.

Like this:

Like Loading...