27/10/2014

I started chopping off the tentacles created by the protruding through-tenons locked in place with wedges and the draw pins. I used my newly acquired Disston no. 12 (ca 1896-1917), which has not been restored completely. I tried to saw off the first tentacle, but found that the saw could do with a sharpening. After that it performed admirably. You will notice that one saw nut is missing as I quickly put the saw back together for this job. I want to clean up the handle and do more work on the blade before finally reassembling it for years of excellent work.

The next tool used is also a rehabilitated old timer. The Bedrock no. 606 was used to plane the end grain flush to the surface of the bench.

I thought it might help in future when observing wood movement in the bench to document what the ambient humidity was around the time the bench was assembled. It remained very stable over the past 4 months ranging between 27-30%.

The bench was then turned on it’s side to get at the stretcher and apron tenons.

Once that was done, I started fitting the shelve. You will remember the Kaapse Swarthout (Maytenus peduncularis) boards I prepared some time ago for this purpose. The cleats were made up of Tasmanian Blackwood (Acacia melanoxylon) grown in the Knysna forrest. The shelve boards were addressed with my Lie-Nielsen tongue and groove plane before cut to final length. You can see how I made slots for the screws

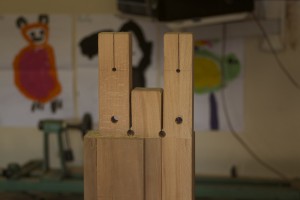

In an earlier post I mentioned that the drawpin holes are not staggered as one should do. Mine are in the same plane. This for technical reasons to do with the design of my tenons. The way I got around this problem was to tap in drawpins that were in the order of 100 mm from the business end and a shorter one (pictured) from the other end to make it look as if they run all the way through the leg.

Each tongue and grooved shelve board were fixed to the cleat with two traditional wood screws sitting in a slot that allows for plenty of wood movement.

The kids helped to assemble the shelve and clearly enjoyed the finished product.

Now I will turn my attention to the legvise. You will find the pictures and write-up in the post entitled “My 18th Century Workbench in Progress 18”

http://www.jenesaisquoiwoodworking.com/my-18th-century-workbench-in-progress-18/