21/1/2016

It is almost a year since I finished my first Rouboesque bench, which gave me ample opportunity to see which design features works for me and which does not. One of several reasons (discussed in detail in this post) why I decided to go with a split-top design was to be able to have easy access to clamp work using f-style clamps along the centre of the bench. I therefore sized the sliding tool trays in such a way that there would always be gaps between them for the above mentioned clamping activities.

What has become apparent over the past year is that although this is a very handy feature I do not need it all that often due to the number and positioning of the holdfast/dog holes. I am able to use holdfasts for 95% of that type of work holding. To add to that, the gaps between the sliding tool trays constantly threaten to swallow tools which the end up crashing into the planes on the shelve below the bench top.

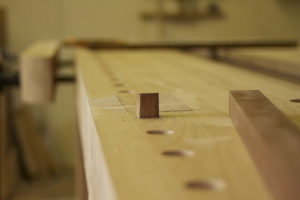

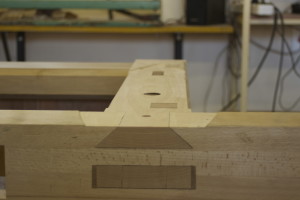

For these reasons I came up with a fairly easy solution. I made two gap fillers that can easily be removed. The pictures should make it clear how it works. The bigger one of the two now act as a more traditional type tool tray that can hold plenty of tools below the surface of the bench top. These gap-fillers do not interfere with the sliding tool trays at the top, which can still slide to expose the tool trays below them.

I hope that the series of photos that follows will make it clear how these minor tweaks prevent the bench from swallowing tools yet retains easy access for clamps when needed.