9/8/2016

Actually, from my feverish and extensive research through the length and breadth of this fair land, a table is by no means compulsory in a shebeen. In fact the only compulsory ingredient is a delinquent supply of Zamalek and/or Windhoek Lager. However in the few exceptional cases where it were found to be present, it was a very welcome addition. So I thought my shebeen should have one, but it took a long long time to find all the ideal ingredients to build a shebeen proof/worthy table.

This project got underway in late July after I managed to secure a beautiful slab of wood from a friend who insisted that he did not want any money for it. In the end I gave him a Record no. 6 fore plane that I restored some time ago as payment. The slab of wood will make an ideal top for a table in Wamboland (our shebeen in the backyard).

Just to remind you what Wamboland looks like, a few pics.

And here it is, a massive slice of Eucalyptus. Unfortunately I do not know much more about the origin and specific species of this wood. I know it came from South Africa and measures up to 2700 mm (length) x 1000 mm (wide at one end and 1200 at the other) x 70 mm (thick). After a bit of research on the net I would say it is probably what is called Rose Gum or Eucalyptus grandis, but by the time it is finished some of our Australian friends will probably give us a better idea of the exact species.

I apologise for the poor quality of this picture due to the contrast in lighting. What I am trying to illustrate is how I marked out the longitudinal centre line on the underside of the slab. Seeing that it is wider at one end than the other, I measured out the centre at each end and tapped in a panel pin. A piece of string stretched between the two pins then helped me to mark out the centre line.

I used trammel points (not pictured) to divide the length of the slab into 5 equal parts along the centre line. The areas to be flattened for the legs were then marked out perpendicular to the centre line at the intersection between the 1st and 2nd fifth, as well as the 4th and 5th fifth. I hope that makes sense to native English speakers.

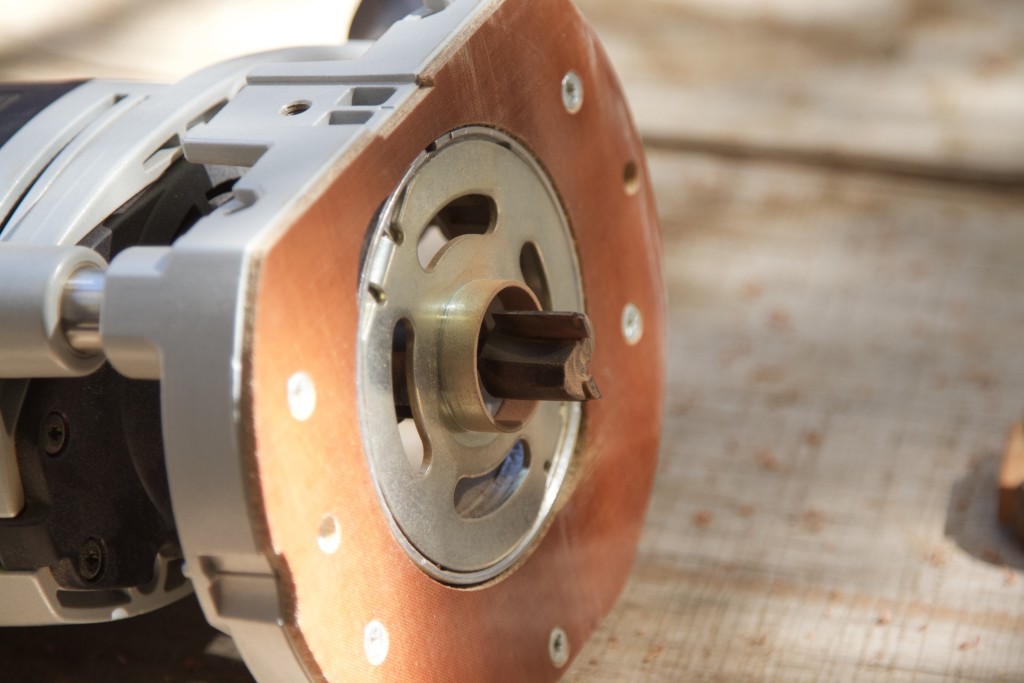

The first of these areas were flattened using my Festool router with the guide rail. I propped up the rail with bits of wood to stop it from bending. This was a very unpleasant experience. I have developed an allergy to electrical routers. They make too much noise and feel very unsafe to me.

The waste was removed by chisel and a slick (not pictured).

At this stage it was time to start the process of preparing the reclaimed Scots Pine, which will become the undercarriage of the table. I wrote a post on the origin of this wood which you can find here. These beams were first cut to length using my Disston no. 12 24″ crosscut handsaw and then ripped where necessary on the bandsaw. Unfortunately this was also the last job I will ever be able to do with this Chinese made 1982 model bandsaw, as it raised the white flag after an admirable career. Now I am in the market for a good affordable bandsaw, which is something that is probably impossible to find given the #Nenegate #Zuptamustfall #Nkandla #Failedtoupholdtheconstitution #Paybackthemoney #Khwesi #Itookashowerafterwards #eleventyseventyhundred #UntilJesuscomes-induced currency tragedy. RIP my dear friend, you have served us well (in reference to the bandsaw, not you know who).

8/9/2016

OK so back to the top. The second of the areas that needed flattening had quite a big bump in it. I decided to use my Festool tracksaw rather than the router.

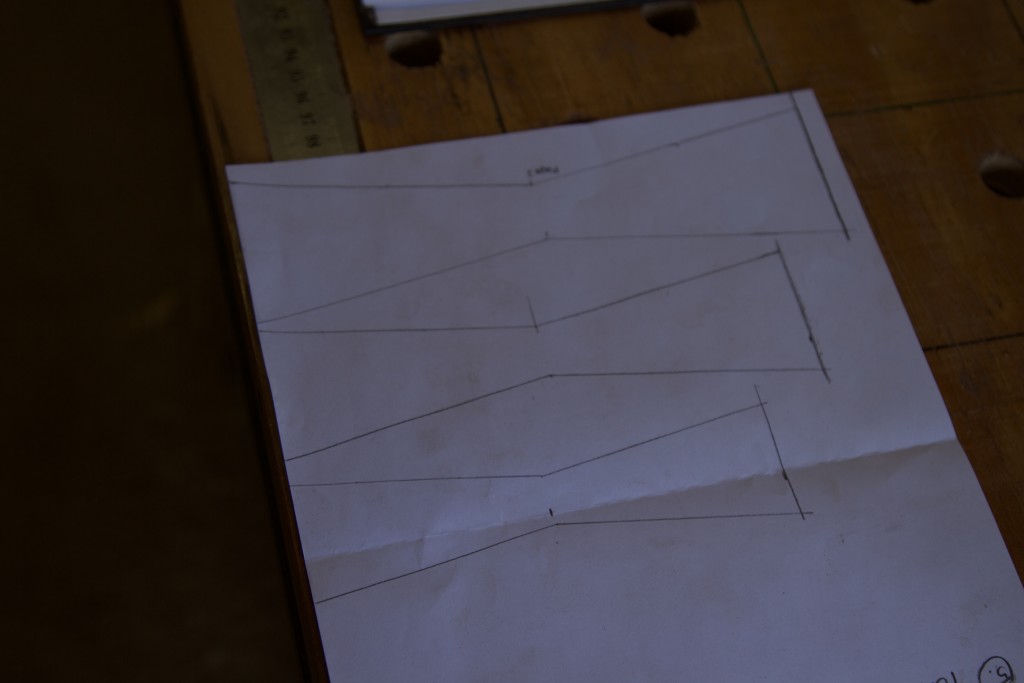

As you can see below, I again propped up the guide rail with bits of wood until the two winding sticks were lined up perfectly. This ensured that the two flattened areas would be in the same plane (or wind free if you like).

So in this case I made a series of cuts checking the orientation of the guide rail with the aid of the winding sticks prior to each cut.

I got lucky in that this area ended up “open” on one side, which allowed me to get in there with my shop made scrub plane to remove the waste (in conjunction with a slick and a chisel of course).

This is the slick I mentioned earlier. The actual slick handle were removed for this job, so I simply seated an old pairing chisel handle as I did not feel up to turning a custom one for such a quick task. It is a Peck, Stow & Wilcox (PEXTO) for the sake of the tool geeks (like me).

Seeing that there is a major crack in this slab of wood running all the way from one end to the other, I wanted to ensure that it does not fold like a book being closed when the top is handled during the building process. It actually feels quite resistant to such movement, but you never know. In order to lend it some extra support I screwed down these two heavy blocks of wood across the crack. I know, I know, possibly more screws than needed #JonathanWhite!! This is of course only a temporary arrangement, while working on the top. Eventually the undercarriage will fulfil this role.

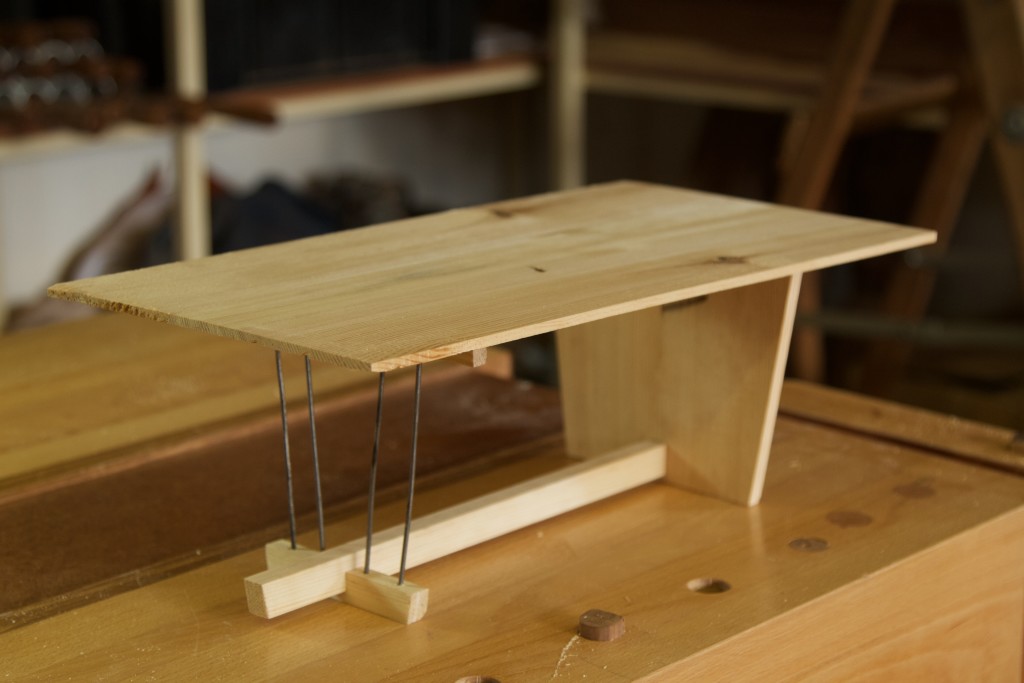

Here you can see the legs, (some of the) stretchers and aprons after hand and machine planing.

The legs being cut to final length.

Hand sawing of joinery.

12/9/2016

The pictures illustrate a technique that I employee fairly often now. I leave an area of waste which helps to stabilise the sole of my Lie-Nielsen router plane. Once the router plane have the area perfectly flat and to it’s exact depth I remove the waste and use the flat area created by the router plane as a reference surface for a pairing chisel.

For some reason I did not take a picture of the part with the waste removed. Sorry.

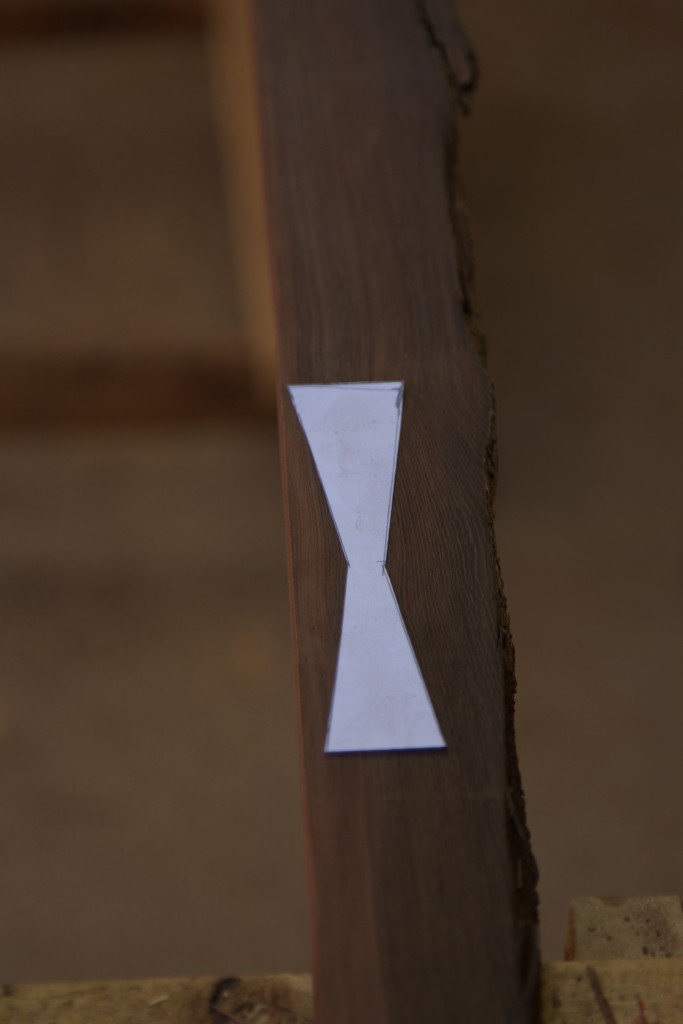

The next major task is to stabilise that massive split in the top Nakashima-style as approached from the side that will face upwards. For this purpose I had to laminate Kershout stock to created massive Dutchmen (aka doveltail keys).

Now they need a cosy new home. As I have described this process previously I will not bore you with it again. The pictures will probably do the job anyway.

Glued into position using slow setting epoxy.

At this stage I am in a race against time as this top is living outside my shop (due to it’s size) so I need to finish my Dutchmen-placement-activities before the rain comes. If we are lucky we might see a few drops around the start of October. The top needs to be safe and sound under roof in Wamboland by then. Then I can happy toil away at the undercarriage (which does fit in the shop) until it is ready to be joined in matrimony.