24/3/2018

Well it has been a long time since publishing the previous post in this series. I do not want to elaborate on the reasons, but cherish the opportunity to be back live with an update.

In the previous post we got as far as preparing the top of the table to the stage of applying tung oil and finishing most of the joinery.

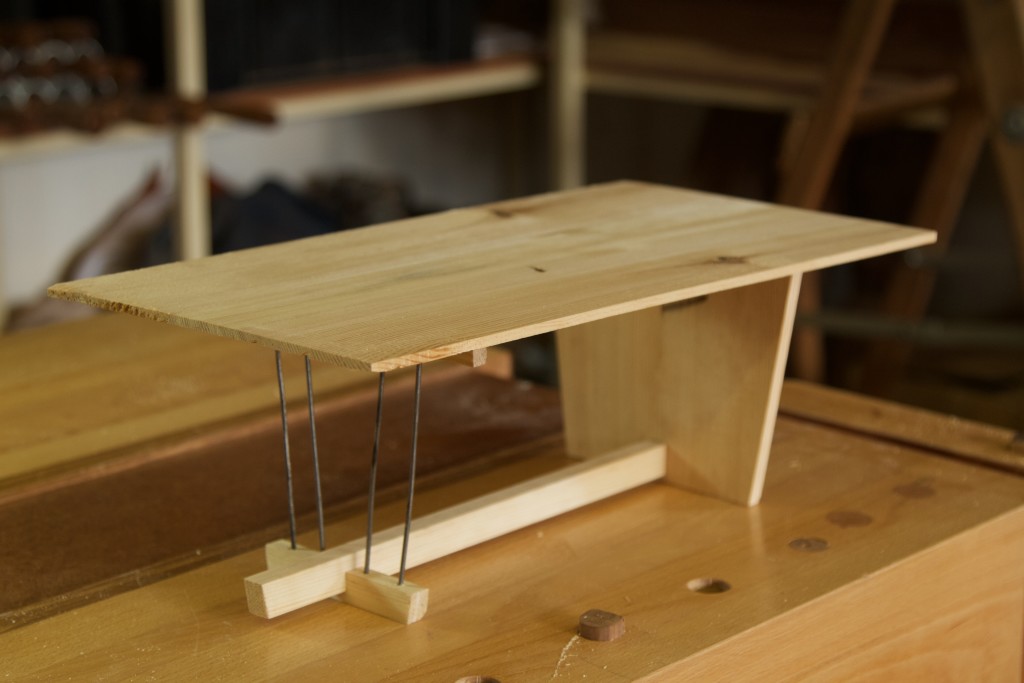

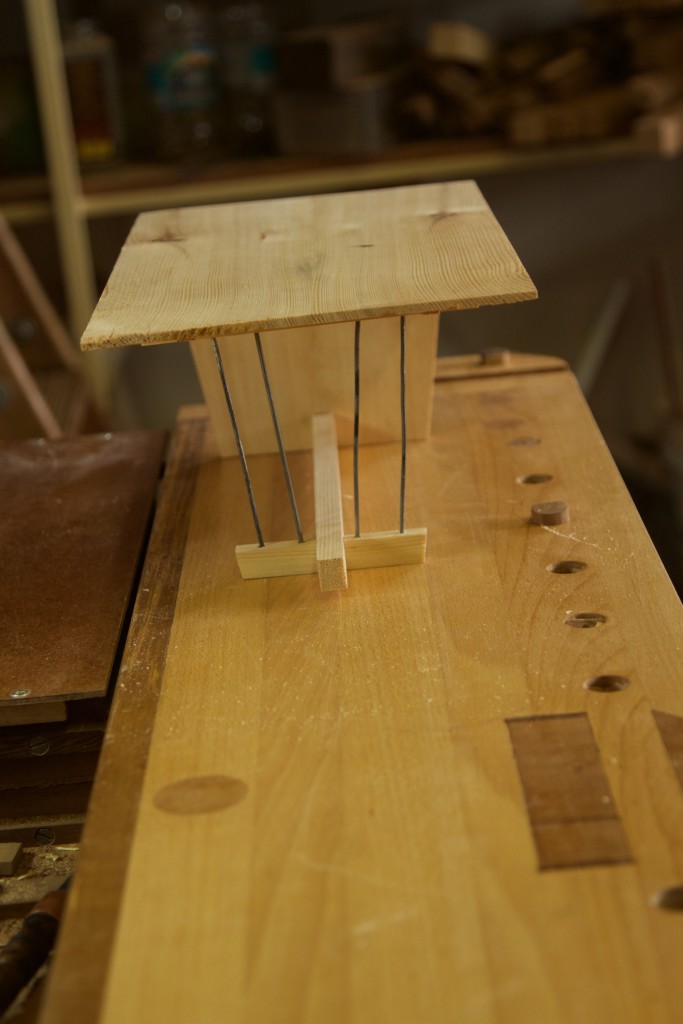

In this edition we will look at the next few stages in the finishing of the top and a little bit more joinery. In the picture below you can appreciate (I hope) what the legs look like in relation to the top, in an upside down universe.

That reminds me, I should probably give you an aide-mémoire of what we are aiming for. Here are a few pictures of the model I’ve built to test the design and dimensions et cetera. It might make the upended universe easier to interpret.

We will start our discussion with some joinery. The über-beam at floor level mates with (please excuse the sexual references, but I am a psychoanalytically inclined Psychiatrist so what do you expect?) the bottom of the Windsor leg by means of a half ass bridal joint (if you like??). The execution of which should be apparent in the following pictures.

After an extensive search for quality Beeswax in Sub-Sahara Africa I finally received something that resembles what the bees actually produced from the Capital of ludicrously embarrassing Afrikaans music. I am of course referring to Snor City (the City of the Moustache) aka Pretoria.

At this stage I was still hunting for blonde shellac, but went ahead with the next phase of finishing i.e. working beeswax into the extremely fine grain of the Kershout using a polissoir Don Williams sent me. He sent me two of these puppies, one of which I used to burnish the surface and the other to coax the wax into the grain. The latter polissoir were first soaked in heated wax to impregnate (there we go again) the fibers of the business end. (Don, these tools work like a charm, thank you mate!)

Below we have a final look at what the Kershout top looked like after burnishing it’s oiled face side.

Now we get into the ancient process of French polishing as performed by a complete neophyte, so please do not follow any of these steps if you know better or saw a qualified person at work. What I did was to rub beeswax onto the surface like so …

The beeswax was then rubbed into the previously burnished surface using an impregnated (now please stop) polissoir.

The next step involves a hardwood block that is used similar to a scraper blade to remove the excess wax. That is followed by buffing off the last little bit of excess wax with a clean grippy cloth (unfortunately not pictured).

The picture below was taken before the buffing with a cloth.

At this stage I received a mysterious package from the US of A. It contained 6 pounds of premier quality lemon blonde shellac powder from that man called Don “L’ Art Du Menuisier” Williams. It was a present straight from heaven. Here in Deep Dark Africa it is next to impossible to obtain anything that resembles the quality of the shellac I received.

I decided to prepare a 1 pound cut to start out with. The idea was that it should be easier to apply a thin cut if the polisher is inexperienced. Before applying anything though, one needs to fashion a makeshift rubber. Mine consisted of old t-shirt fabric rolled into a bit of a tube-like shape wrapped by some more fabric which was tied with a cable tie to form the object pictured below.

In order to get some idea of what I was supposed to do I read the pertinent passages on French polishing in the 1897 classic “Wood Finishing” edited by Paul N. Hasluck. I found the bit where he explained that no one should even attempt to French polish “articles of value before considerable practice on unimportant articles” particularly encouraging. Luckily a few other sources demystified the process sufficiently for me to roll the dice on a table top that took me the best part of two years to prepare to it’s pre-shellac state.

Do you remember Mr. Miyagi? He was Daniel-san aka the Karate Kids’ master in an epic example of American motion pictures. You know the type, the good guys win, the bad guys lose and everyone is happy ever after (unlike real life in the rest f the world). Well what I did was basically the “wax on, wax off” (actually only “on” I hope) routine to apply the shellac. I wiped it on using very tight circular motion like Daniel-san on those old cars that looked like they escaped from Cuba. I applied three layers in one go, as once you have applied the first layer the shellac is already sufficiently dry at the location where you started to repeat the process.

After each set of tree layers the surface was rubbed down with this contraption. I used a shop made sanding block and replaced the sandpaper with 0000 steel wool.

After a good rub with the my new über-tool, I applied another three layers. Miyagi-san continued in this way until the top sported 18 layers. At that stage I was ready to kick Daniel-san’s arse. Metaphorically speaking of course. The effect of my efforts up to that point can be seen in the picture below.

The top then received another sanding with the 0000 steel wool. Now I need to find a varnish that will add a hard shell. I am still not too sure what that might be, but would take advice from anyone who would like to send me some! Just joking of course.

I decided to mask off the edges to ensure that they stay dull in appearance to create contrast and visual interest.

Let’s get back to the joinery. The heavy beam that runs close to floor level is joined to the trapezoid leg by means of a wedged through tenon. For the mortise I drilled out the waste with an Irvin pattern auger bit and chopped to the knife line with a chisel.

The tenon followed.

The fit seemed quite acceptable.

The mortise for the wedge has a 9° slope. I used the Charlesworthian prop pictured below to ensure accurate chiseling of the slope.

So okay, one of the reasons for my radio silence is that my father passed away after a very short battle with cancer. Seeing that he taught me almost all I know, it has been a bit weird spending time in the shop. I am sure we will discuss this in more detail at some point in future as it must be a fairly common phenomenon for a lot of woodworkers.

For now however, I thought it pertinent to include an impromptu design alteration to dedicate the piece in his memory. The carving was done free hand with a 1/8″ bevel edge chisel after drawing the design free hand on the tenon with a pencil. It was repeated on the opposite side.

The enforced lamination of the beam were disguised by the same set of beads as was used on the Kershout beams of the Windsor leg.

My son Didi prepared for his entrance exam at Bishops in the shop while I worked. He has his heart set on becoming a Bishops Boy next year when he goes to secondary school.

While Didi got stuck into his books, I softened the look of the Windsor legs. The beam that forms the foot of the leg received a very slight curve (to it’s sole) to ensure that it would sit stable on an uneven floor and the sharp edges were rounded over somewhat.

I like doing this very much in an organic fashion. I mark out the curved sides with an appropriately sized washer and draw the guiding lines across using a finger as a fence. It is then shaped by hand using two rasps and a sanding plane.

I quite like the way the beads disappear in the picture below.

All that remained was to apply a tung oil-turps mixture, which would then have about three weeks to settle during the Easter break before we apply beeswax. I tend to try and keep the surface wet with the oil mixture for an hour or so and then wipe off the excess with a clean cloth.

Here are a few pre-oil pics.

Followed by just-oiled pics.

The book matching of the below aspect is starting to emerge quite nicely.

So there we go. Hopefully back with a vengeance.