11/1/2016

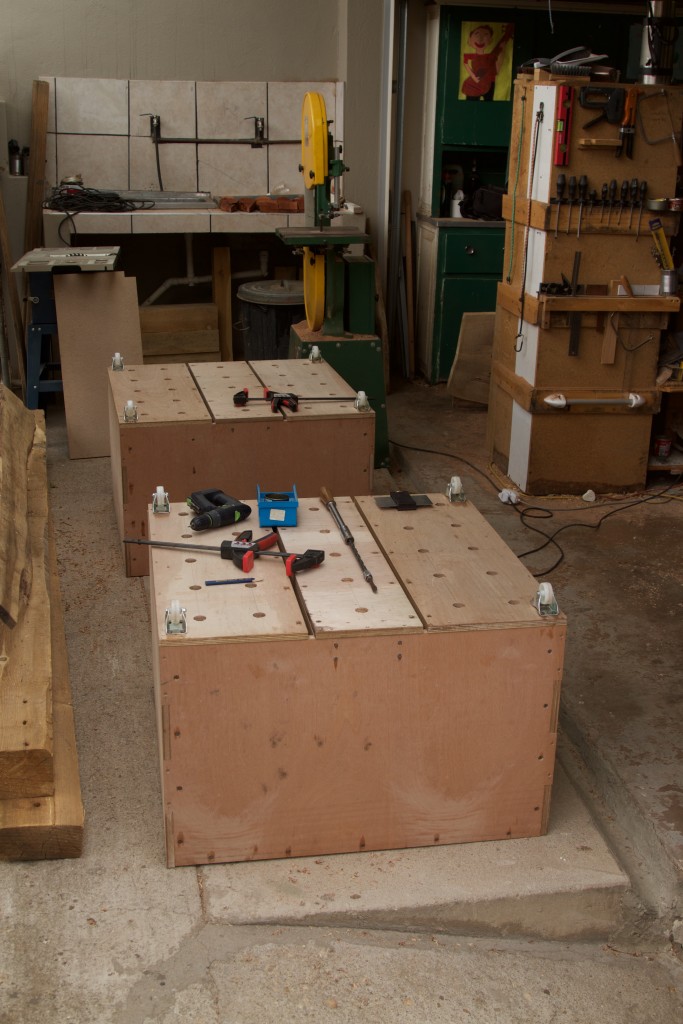

After my (by now) usual antique shop rounds in the Garden Route area during December, these are the fruits of my looting.

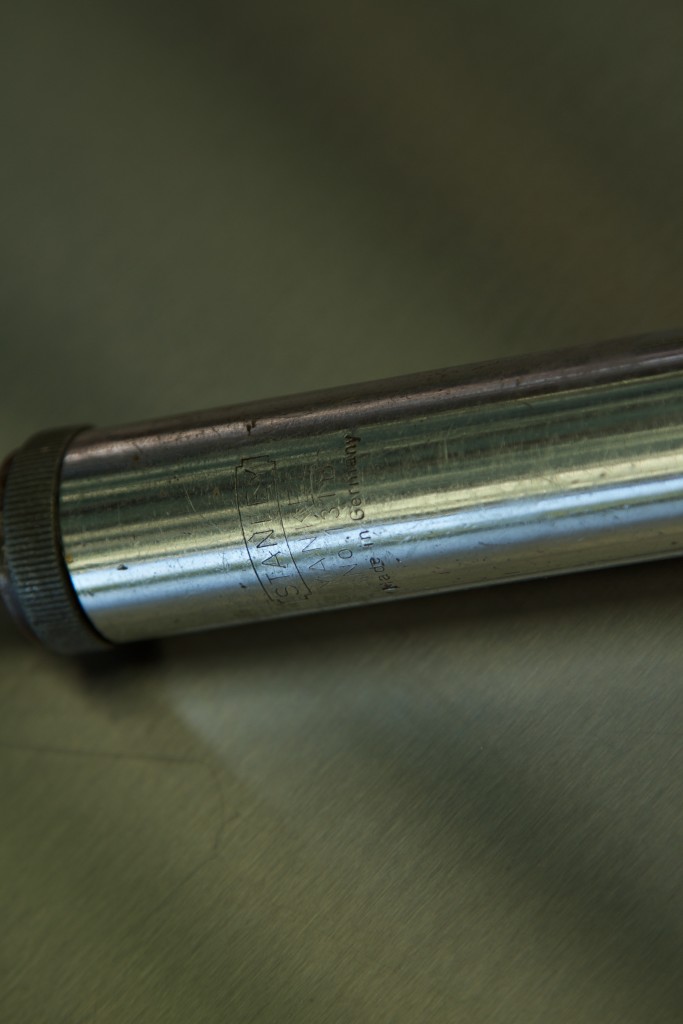

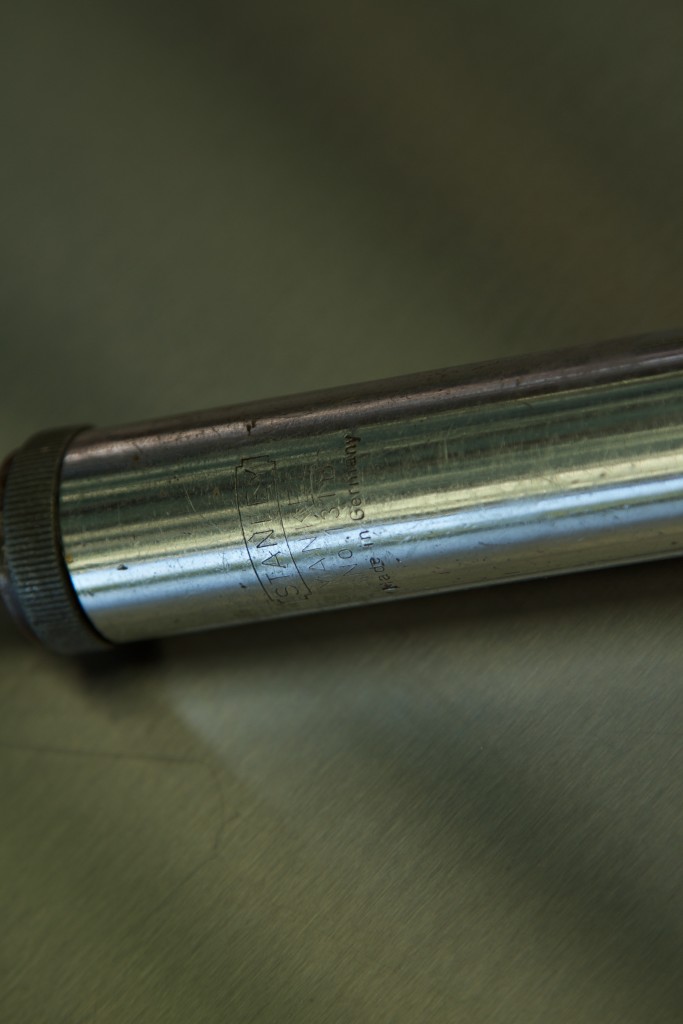

A no. 131B Yankee ratcheting screwdriver.

I already have two of these so this one will probably become the property of one of my young apprentices, Connor Burmeister-Nel. It has both the Stanley and Yankee brandnames on it and was made in Germany, which means that it was definitely made after 1946 when Stanley bought out North Brothers. It is the first one I see that was made in Germany, so I asked Robert Demers of The Valley Woodworker to investigate what that means in terms of it’s age. (Bob has subsequently published this excellent article on the topic)

The other no.131’s I own were both made in the UK. One of those also sport both brand names and the other has only the Stanley brand name. The latter screwdriver also has a plastic handle which is not nearly as nice to work with as the wooden handles on the other two. What that one has going for it however is that it was bought new by my father-in-law back in 1978. It will therefore become my son Didi’s “Yankee”. I bought the pictured Yankee for US$ 7.41 on todays exchange rate.

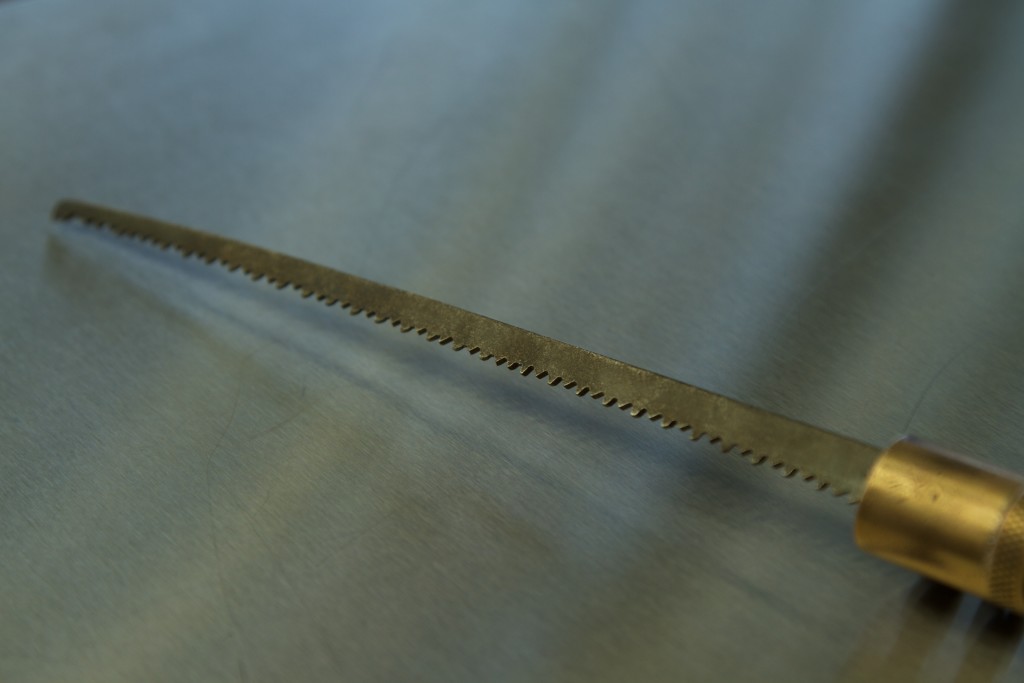

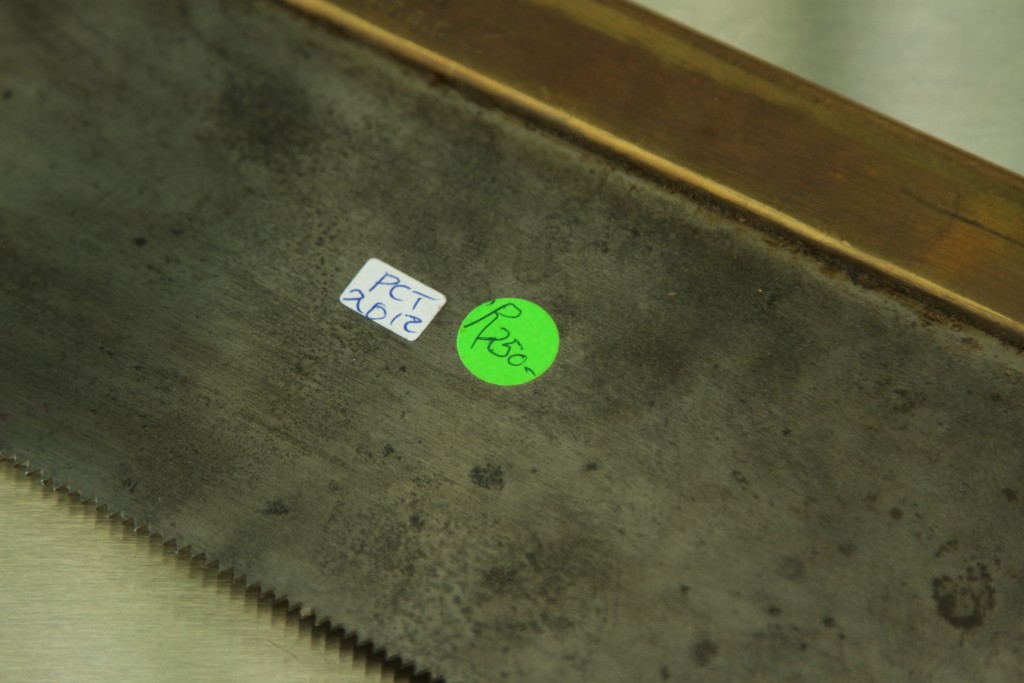

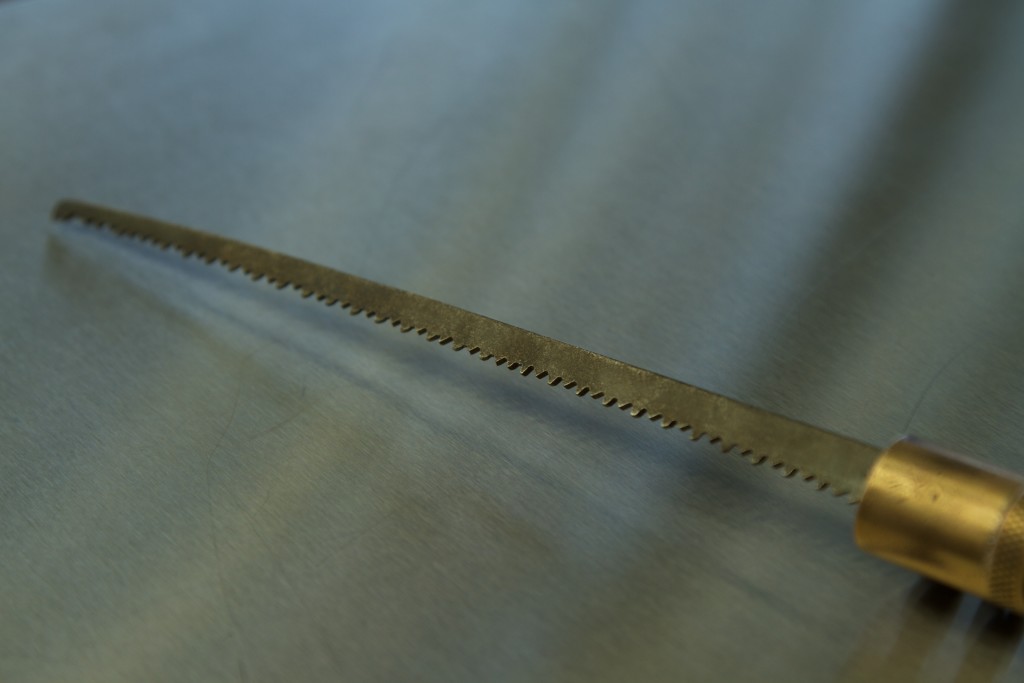

A key hole saw

At least that is what I think it is called. It has no makers mark, a very nice brass thingy (once again JNSQ woodworking delivers cutting edge technical terminology) that holds the blade and a Beech handle. My guess is that it is British in origin. (US$ 10,38)

I bought this spanner for decoration purposes only. It is massive to say the least. It is striking a pose with a shot glass loaded with Jaegermeister. (US$ 2,08 The metal must be worth more than that)

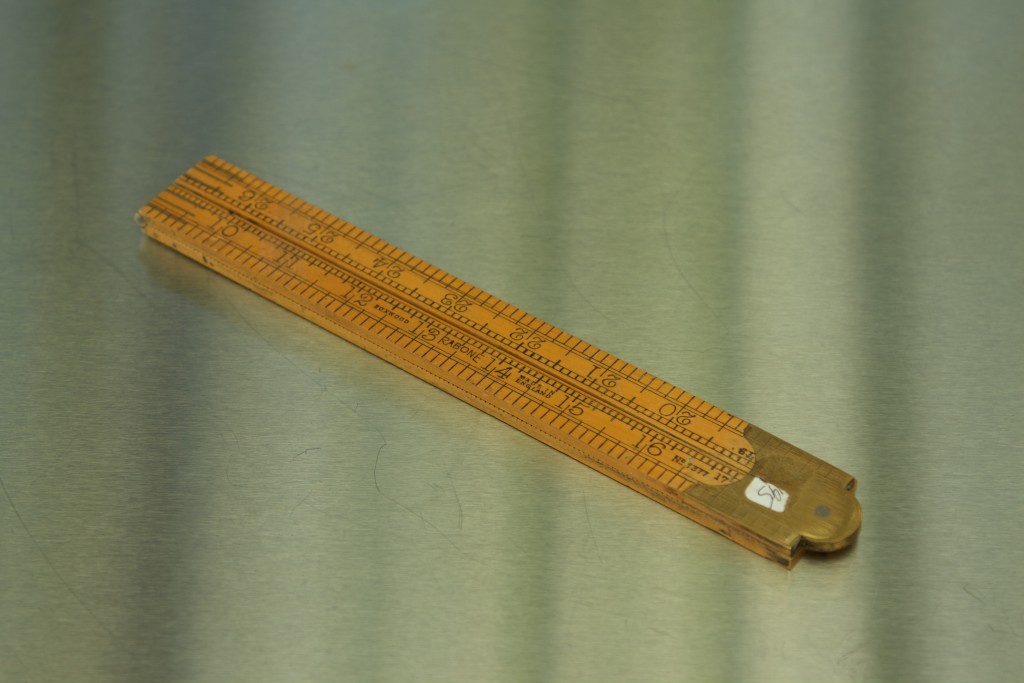

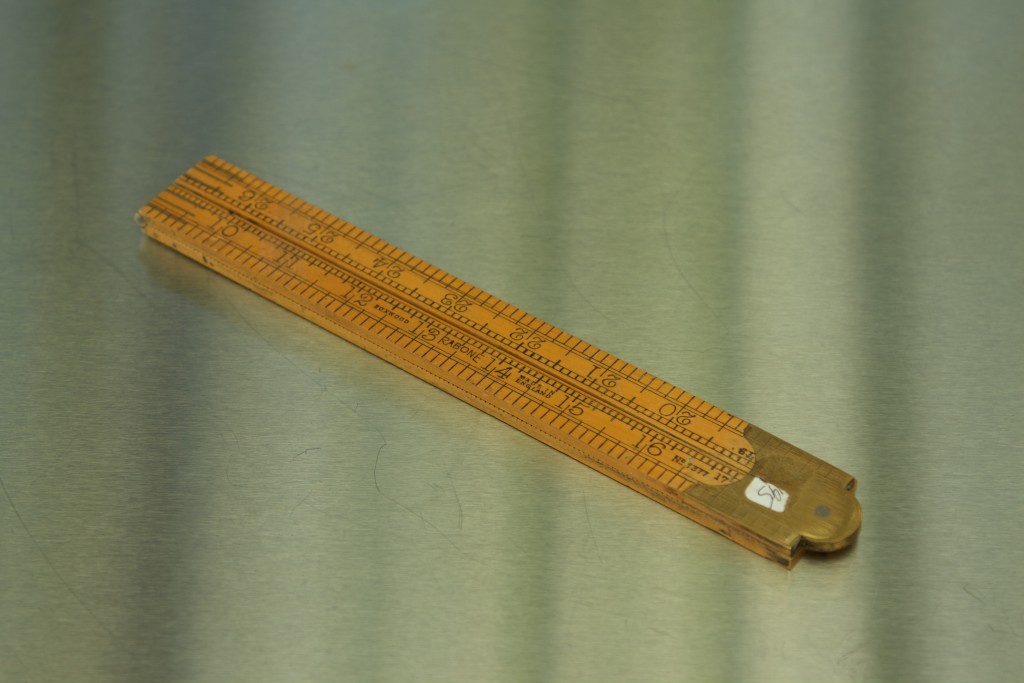

Rabone 3′ two fold boxwood rule

It looks to be pretty much unused. (US$ 11.56)

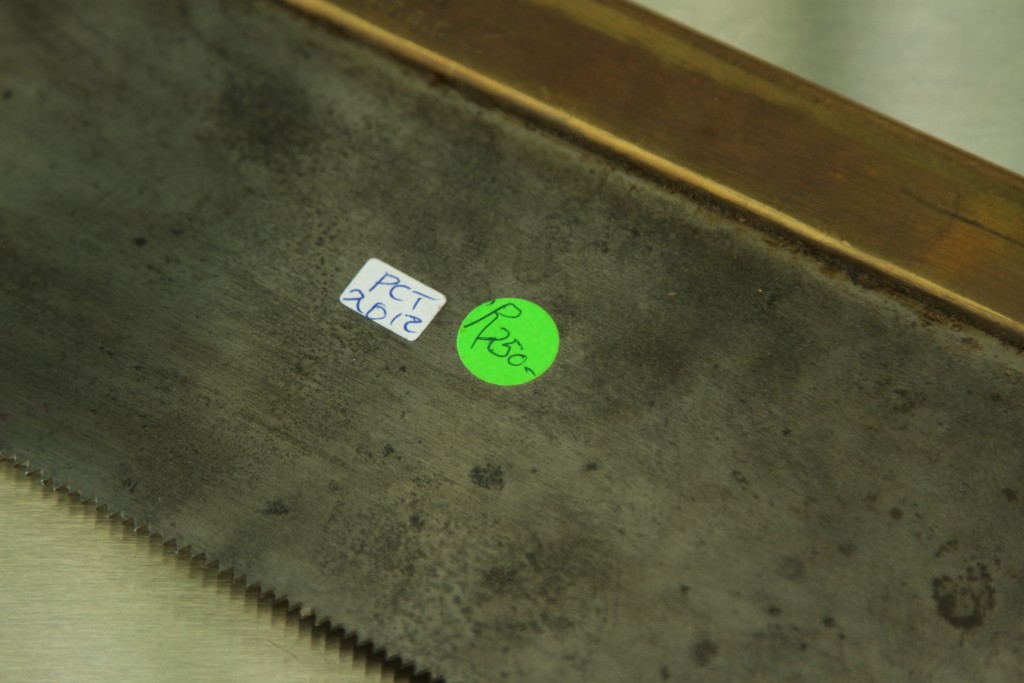

S. Tyzack & Son back saw

It is in a very good condition and will make a very fine user after some minor rehab. I plan to joint and resharpen. I paid US14,82 and from the looks of it, it must be worth at least US$ 100. If anyone has more intimate knowledge of these saws and their history I would love to hear from them.

Stanley no. 49 bit gauge in original box

It is clearly brand new/unused. They are used a stop gauge on one’s auger bits. (US$ 5,87)

Handmade 6″ dividers (US$ 10,38)

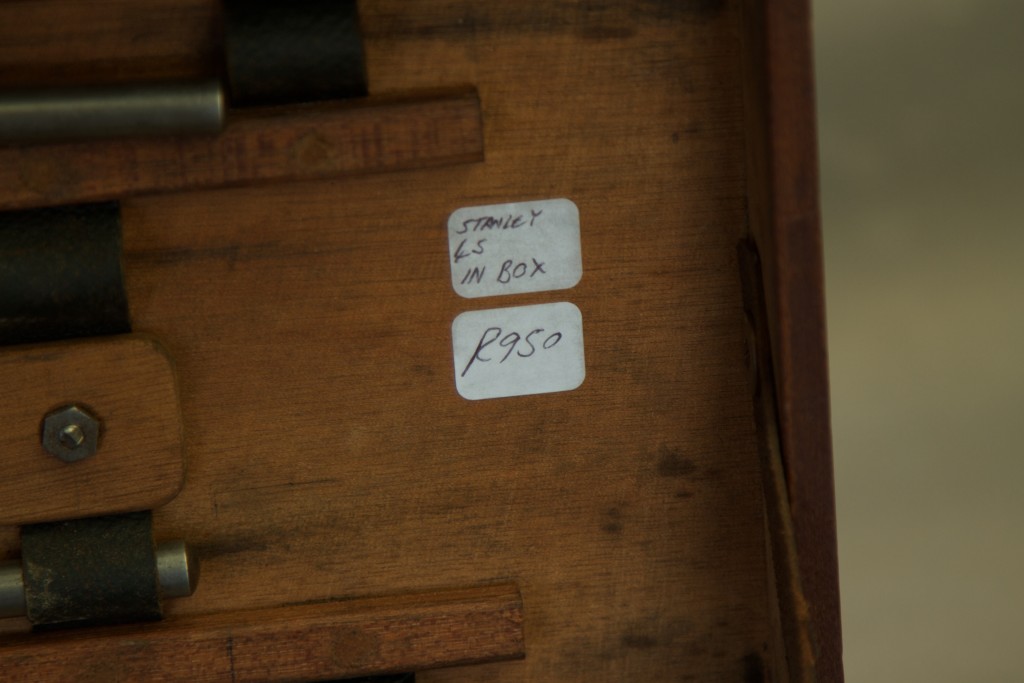

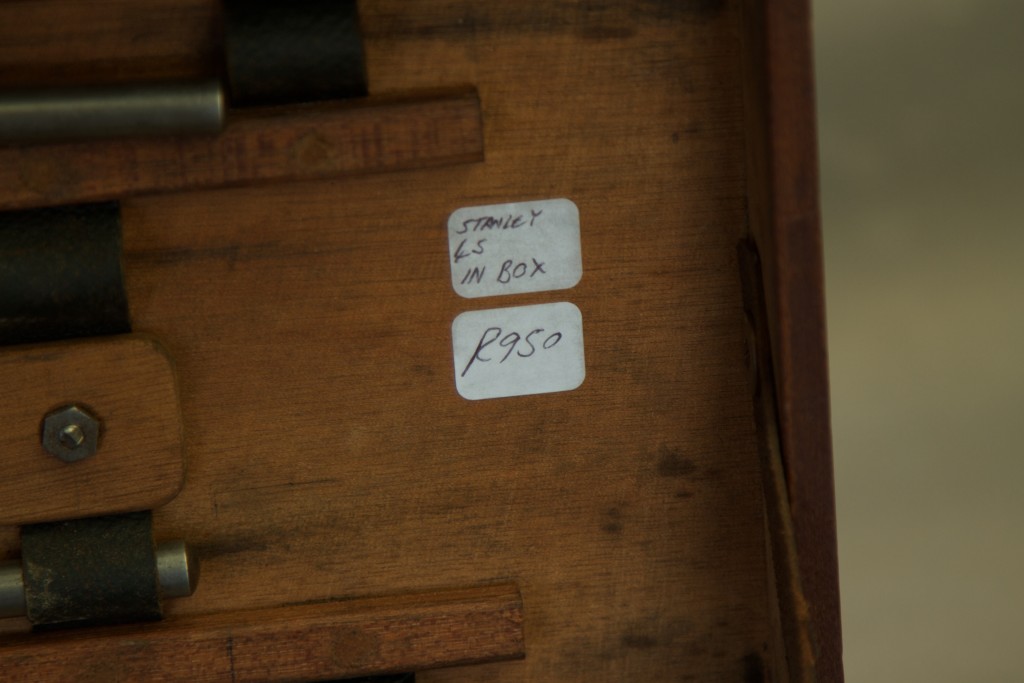

Unused Stanley no. 45 combination plane in wooden box

All the parts are present apart from possibly the screwdriver that came with some of these sets. It is clear from looking at the fence and blades that it has never tasted any wood. I paid US$ 56. Similar sets usually cost between US$250 -300 from Jim Bode.

Cross peen hammer

Unfortunately I did not take a picture of this little hammer before replacing it’s handle and doing some cosmetic/functional reshaping of the head. I furnished it with a Assegaai handle, which was shaped using a drawknife and card scraper. It was wedged using a wooden and a metal wedge. I bought it for US$ 1,48 in a pretty dreadful state. It had a metal pipe for a handle that looked like it was fitted by a backyard butcher.

A no. 130A Stanley Yankee ratcheting screwdriver with three bits

The is the medium sized model in a superb working condition. It was given to me by my cousin (once removed) the Urologist. I am not sure whether there might be some Freudian subliminal meaning to his gesture (coming from a Urologist??), but it was much appreciated. This screwdriver originally belonged to his uncle who died some years ago. I already had one of this particular size, which I will now be passed on to my son. Then I can use this one given it’s history.(US$ 0)

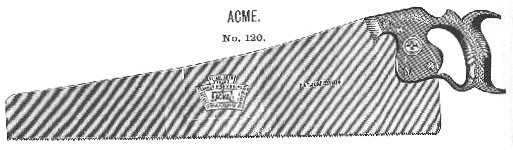

Disston D-8 (26″ 7 tpi) circa 1947-53 (based on the medallion) and made in Canada

This saw was also a present from my cousin. It belonged to the same uncle. I plan to straighten the blade, make a new handle (based on a Disston no. 120 from the 1876 catalogue) and sharpen it for my apprentices. Comparing it to my two pre-1900 Disston no. 12s, it is shocking to see how the saws of this iconic company deteriorated over a 50 year period. The handle is can only be described as inferior in every aspect to the earlier offerings by Disston.

Mark Harrell of Bad Axe advised me not to waste the time and effort, but it will not cost me any dough and you always learn something from a restoration project even if it is that you should not have bothered. He did however say that the quality of the blade should be top notch, but had some concern regarding the amount of rust.

I would appreciate more information on any of these tools, so to all those tool geeks out there, go mental.

26/1/2016

Here is some feedback I got from my friend Bob Demers (aka The Valley Woodworker). He is such an expert on this topic that I though everyone could benefit from reading this:

BTW here are some things I noticed in your last post on your loot 🙂

That Disston saw is from the 50s judging by the poor resemblance of a once gracefully shaped handle, sad isn’t …

If you do make a new handle, and I encourage you to do so, pay close attention the holes locations, and the orientation of the existing hand hold on the handle

Because that is what determined this saw hang angle

http://thevalleywoodworker.blogspot.ca/2015/06/part-2-mysterious-saw-hang-angle.html

I would not be too concerned with the blackened appearance of the saw blade. Although I understand why Harrell says you should not bother too much with it (because they are plentiful and better ones can easily be found, around here in NA anyway), as long as there is not tooo much pitting, all is fine.

Yes, normally a shiny plate work to our advantage, since it glide easier and by watching the wood reflection on the blade you can see easily when you are at 90 degrees

BUT, no big deal (Sandvik even made saws with a black Teflon like coating on some of their saws, what is more important in this case is the reduced friction.

That even blackish coating is often a layer of oxidation that prevent further rusting by making a barrier.

I would simply scrape gently the blade surface with razor blades and some sort of penetrating oil like WD40 (very messy uses lots of paper towels or rags)

It should smooth out the blade, remove any rust incrustation and protect the maker etching on the blade.

If you were to sand it, you would probably obliterated quickly.

I would finished the job with a light sanding using a flat solid block (piece of wood, no sponge, cork or other flexy bit, in order to protect the ewtching.

Finished the job with a light wax and buffing application and voila, one slick blade gliding in the wood regardless of blade color 🙂

It would also make a great candidate for practicing saw sharpening and setting.

Your so called keyhole saw is known as a Pad Saw, and you are correct in saying that it looks English, cause it is. Often the only markings to be found are on the blade itself

And yes, it can be used as a keyhole or small compass saw.

http://thevalleywoodworker.blogspot.ca/2015/06/specialty-saws-cutting-curves.html

Like this:

Like Loading...