3/8/2015

I found this single bevel axe head in a “cash converter” store in George while visiting the Garden Route in June 2015. I had to fork out the astonishing amount of R125 for it. (bottom of the first picture)

Some idiot put a bevel on the non-bevel side, but otherwise it was in top shape.

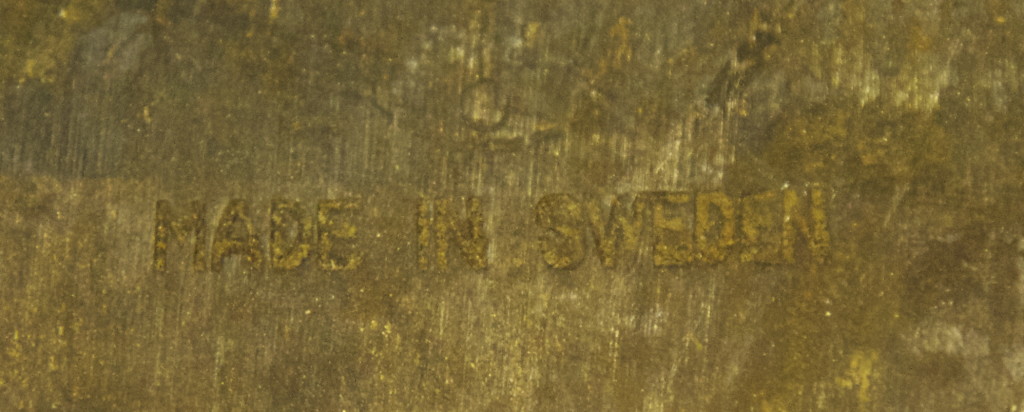

The only mark on it reads “Made in Sweden”.

29/1/2016

First I had to get rid of the unwanted bevel and then proceeded to grind a fresh bevel on the correct side of the head. This took quite a while as I was careful not to overhead the steel, which would result in a loss of temper. You can see how I clamped the axe head to a piece of timber which is shoved against a suitably place object (read foot) to ensure a constant grinding angle.

The handle was made from a piece of Assegaai (Curtisia dentata) using the bandsaw, draw knives, rasps and a card scraper.

1/2/2016

I am proud to report that I did my first bit of blacksmithing to create this cold steel wedge. It was a scrap bit of steel that received an almighty pounding. I do not have a blowtorch (yet), but can report that aggression can sometimes yield products of beauty. The steel is soft enough to be shaped without heating.

As you can see here, I used a wooden wedge and the metal wedge to secure the handle.

Of course I drove the metal wedge one blow of the hammer too far, which resulted in the timber below the axe head splitting.

As I was not in the mood to make a new handle, I simply installed a wood screw to inhibit a potential extension of the split.

15/2/2016

To complete the rehab I made a nice game leather sheath for the side axe. Now the only thing left to do is to find suitable green wood in Namibia to hew into chair stock.

That axe head is very cool. I don’t know where you find the time to do all this. I’m kind of jealous 🙂

I really like that assegaai. Beautiful stuff.

Nice job, on both the tool and the leather sheat.

Look carefully above the words Made in Sweden, I think I see a faint logo or markings. look like the bottom of an arc on each side ?

It look too round to be a scratch.

Bob, who promise to get on with your Yankee tools ID soon 🙂

Thank you Bob, I will inspect the head a bit more and report back.

Congratulations with your epic rise to stardom in the woodworking blogosphere. Both Jonathan and I are quite jealous as you’ve had 10 times more views in one year than we’ve had in 3. Well done, you deserve it mate.

I cannot wait to hear what you come up with in terms of the Yankees.

Speak to you soon.

Gerhard

Came out nice, Gerhard, not familiar with the one sided bevel.

Something else. Are you 100% sure that is Assegai? I don’t know it at all and have never worked with it. But some years ago I started collecting from Rare Woods little African timber samples of about 20 x 7cm. Got one from them, similar to your Assegai, marked as White Pear. Differs quite a bit from my Hard Pear sample. Don’t really see on the internet pics of either White Pear or Assegai.

But if you’re sure, I’ll re-label my sample.

Greetings

Hi Frank

Nice to hear from you mate. Usually Assegaai and Witpeer look quite different from each other in my experience. Witpeer has a cream to brown colour spectrum whereas Assegaai is a lot more orange with reddish brown streaks. Having said that, I have found a few boards in my collection over the past few years that I initially though was the one and it turned out to be the other. The shape and appearance of the darker streaks in both of these woods can sometimes look very similar, but once you plane it to expose the clean wood, the colour usually tells you which one of the two you are dealing with. Hardepeer tends to be more yellow to brown and can look a lot like very old Yellow wood some times, like the stuff that spent 200 years doing duty as dakbalke in an old Cape Dutch farm house. Hardepeer however usually has a lot more interesting stuff going on in terms of Colour variation and grain patterns than Yellow wood.

If you go to Peter Follansbee’s site (https://pfollansbee.wordpress.com/) or search for some of his videos, you will see how these side axes can be used quite efficiently for what they call hewing. This seams to work best with green wood, but I have (as of yet) no personal experience of doing just that. First need to find suitable green wood to work with, but at least I now have the axe to get stuck in when the opportunity arise.

Hope to see you soon in Cape Town.

Gerhard

Regarding Bobs comment, looks like you have a Hults Bruks there!

Regards

Dear Frank and Bob

You guys are out of this world. I had a careful look and you are quite right. It seems to be a Hults Bruk Swedish axe. If you go and check out their logo on their site (http://hultsbruk1697.se/) it is exactly what can be seen above the “Made in Sweden”. Impressive work boys and thank you very much!! It therefore seems as if I bought a very nice axe without realising it.

Have a wonderful day.

Gerhard

Good eye Frank! Woah, good score Gerhard 🙂

Bob