14/9/2015

As the bench is approaching it’s glue-up stage, it is as if my toil has taken on a new verve characterised by a strange mixture of pep and angst. At this stage I plan to get it assembled in the next couple of weeks.

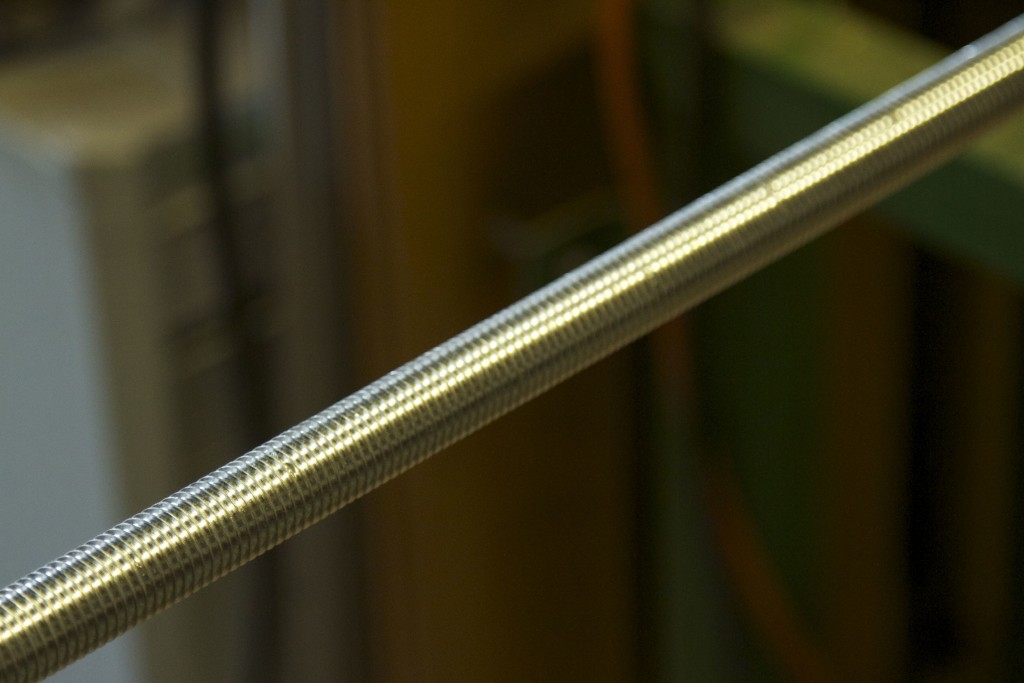

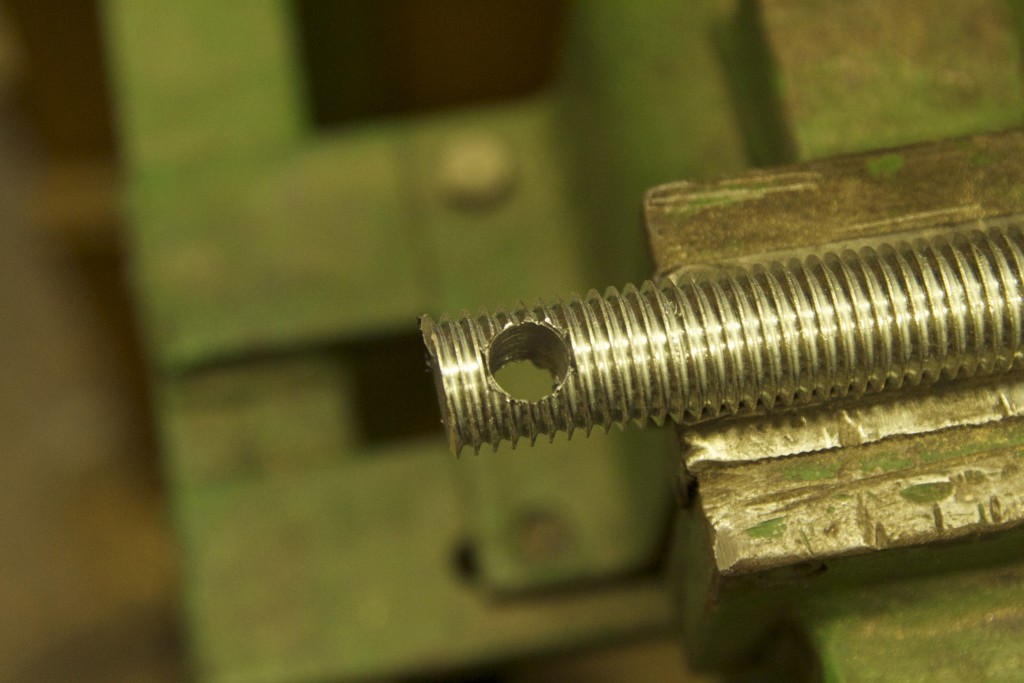

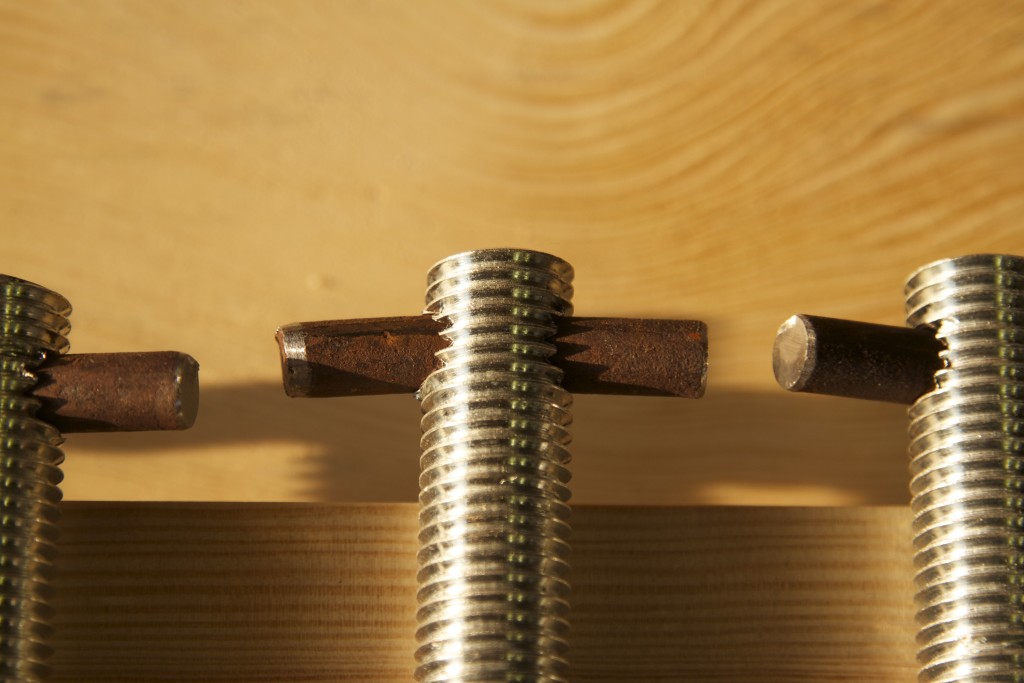

The pictures below should suffice as an explanation of how I created the custom bolts, which will fix the top beams to the apron in conjunction with the Roubo joinery. As you can see, it is made up of galvanised 20 mm threaded rod and scrap mild steel rod forming a T. The ends of the T-piece is bent downwards ever so slightly to ensure that the custom hardware exert pressure across it’s entire length once properly fastened. We will call this the … wait for it … Marx-Roubo Bolt.

The idea is that the top of the T will be embedded/entrenched (and covered up with wood) crossgrain in the top, which will prevent it from rotating when it needs tightening due to possible seasonal movement of the wood. It also provides quite a wide area across which it exerts downward pressure to keep the top beam tight against the apron.

A task that I though would take me 30 min has been dragging on for the past week. I thought that my Stanley no 77 dowel machine equipped with a ½” cutter would make short work of the 24 dowels (½” x 6″) I need for the bench. It turns out that perfectly straight grained Assegaai (Curtisia dentata) tends to fight the machine all the way.

I chose Assegaai as it is very hard, yet extremely flexible and does not move much at all once dry. The problem is that even with a very sharp blade it is hard work to make the dowels. On the upside, it is absolutely perfect dowel that emanate from the no. 77’s hind side (third picture). I will post some more pictures once the dowels are finished.

As you can see the kids also got stuck in once my arm was completely moer-toe.

By the way, this is the stock I prepared for the no. 77. It is perfectly straight grained Assegaai pointed using the legendary new tool in my shop known as the BPS (Boorish Pencil Sharpener).

Due to the extreme exertion inflicted by the dowel making activities, I had to come up with ample “legitimate” reasons to take a break. One of those was to check whether I prepared enough Without to span the entire length of the shelve below the bench.

OK, so I have enough Without, … now what? Back to the Dowel machine? Eish!!, … maybe not just yet. How about fitting the last set of stretcher tenons? That sounds better.

These beautiful girls assisted me to do just that.

The legs were finally cut to length using my Disston no. 12 crosscut saw. It is without a doubt one of my favourite tools and probably one of the best that was ever made.

While all this was happening, my son Didi got stuck into making the Dominos we need. It was very good practice to hone his sawing skills.

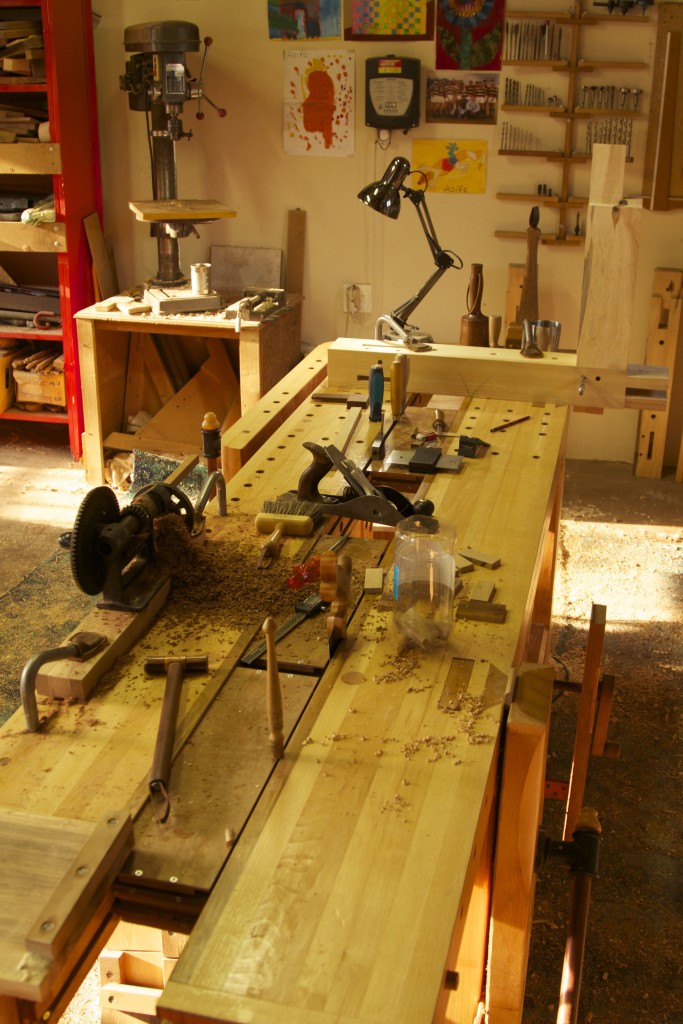

This is what a bench looks like where several different jobs are being done at the same time. I like jumping from task to task and have different stations set up for each. This way I do not get bored or tired doing one thing for too long. It works well for me, especially when there are tasks that necessitates serious stamina, like drilling a gazillion dog holes with a bit and brace, hand sawing 4″ x 5″ legs to length, creating dowels from Assegaai by hand etc, etc. The down side is of course that you need more workspace.

I am interested to hear what others think of this type of approach.

Here I am using the ½” bradpoint bit to mark out the middle of the draw pin (Assegaai dowel) on the tenons. Once I know that location it is fairly easy to mark out the required offset for the hole through the tenon.

Interesting learned a few new expressions, I have no idea how to pronounced them But I’m going to have fun with some of them 🙂

You have a Stanley No 77, I’m jealous now… Last time I saw one or use one was in school, a long time ago.

And, Ja, I do similar in my shop, having a few things on the go at the same time, keep me distracted and effect maximum mess in my shop.

If a clean shop is a sign of sickness, then I’m very healthy :–)

Hang in there, nearing completion.

Bob

Hi Bob

I had such a laugh, reading your post. It is very impressive to see how you use the Afrikaans like a local. You will have a ball in Africa, you are a natural! My first thought concerning your comment on a clean shop being a sign of sickness, was the images of Jonathan’s shop I have seen on his site (The Bench Blog). He must be one extremely sick individual. We might need to send out a medical resque party to the Olympic Peninsula ASAP!!

Anyway, was the no. 77 as challenging to use as I am finding it, in your memory? Or is it simply a case of using wood with too much attitude?

It is such a privilage to have these discussions on woodworking topics with people like you. Thank you for that.

Kind regards

Gerhard